Folding Cartons

Folding cartons are paper-based packages that store, protect, and market consumer products. Retail stores, pharmacies, grocery stores, and other marketplaces rely on folding cartons to feature products. These packaging solutions are crucial in influencing consumer purchasing decisions, so they must make a strong first impression. We’ll discuss exactly what folding cartons are, how they’re made, different types, and common applications.

What Are Folding Cartons?

Folding cartons are exterior product containers made of paperboard. The carton can be made in many sizes and shapes and printed with any design before being cut and assembled. Since the material is easy to manipulate, folding cartons can range from simple rectangular boxes to complex structures with cutout windows or interior pieces of paperboard. Folding cartons are extremely lightweight, making them cheap and easy to ship.

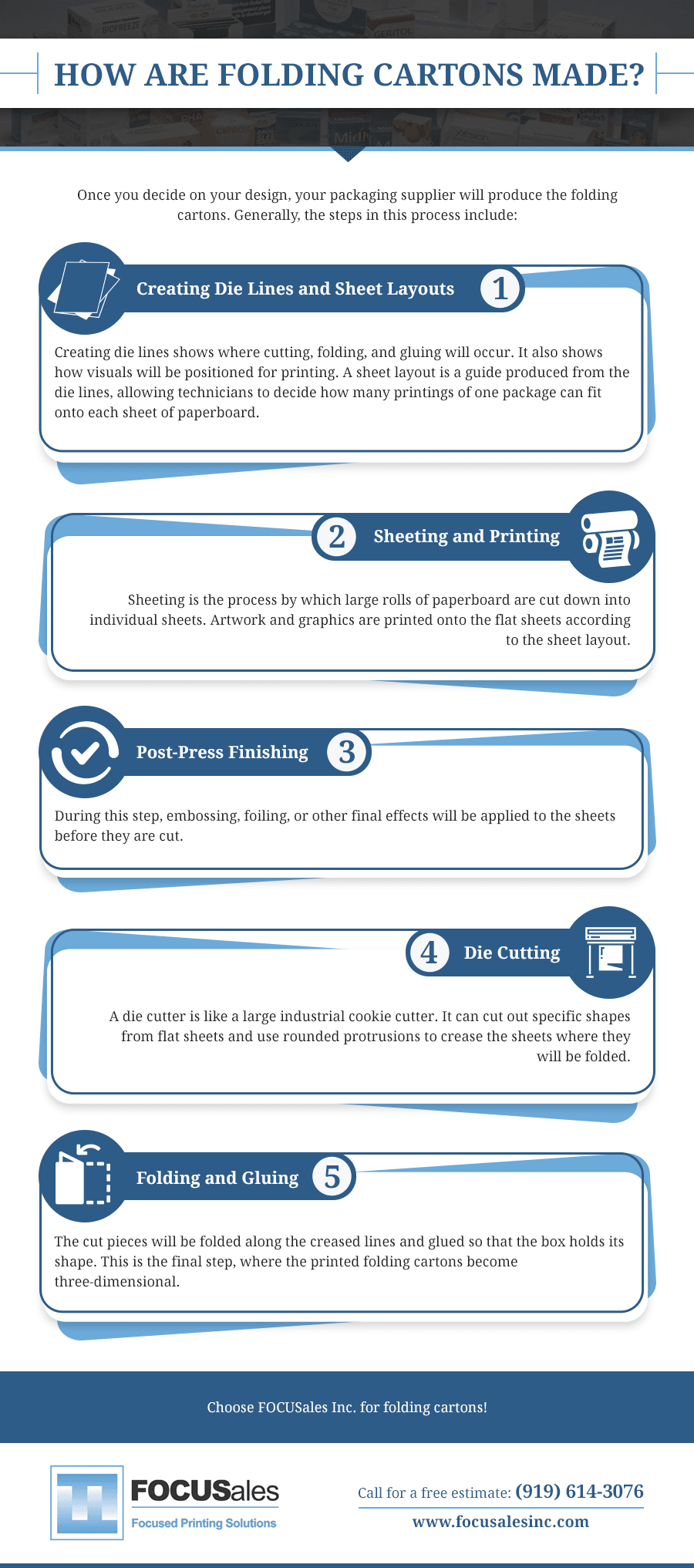

How Are Folding Cartons Made?

Once you decide on your design, your packaging supplier will produce the folding cartons. Generally, the steps in this process include:

- Creating Die Lines and Sheet Layouts: Creating die lines shows where cutting, folding, and gluing will occur. It also shows how visuals will be positioned for printing. A sheet layout is a guide produced from the die lines, allowing technicians to decide how many printings of one package can fit onto each sheet of paperboard.

- Sheeting and Printing: Sheeting is the process by which large rolls of paperboard are cut down into individual sheets. Artwork and graphics are printed onto the flat sheets according to the sheet layout.

- Post-Press Finishing: During this step, embossing, foiling, or other final effects will be applied to the sheets before they are cut.

- Die Cutting: A die cutter is like a large industrial cookie cutter. It can cut out specific shapes from flat sheets and use rounded protrusions to crease the sheets where they will be folded.

- Folding and Gluing: The cut pieces will be folded along the creased lines and glued so that the box holds its shape. This is the final step, where the printed folding cartons become three-dimensional.

What Are Some Types of Folding Cartons?

Folding cartons are distinguished by their closing type, how users should interact with the box, and the products they contain. Here are the most common styles of folding cartons.

- Straight tuck boxes are one of the most common types of folding cartons. The top and bottom closure panels are both attached to the main piece that forms the box. Both closures fold from front to back in the same direction.

- Reverse tuck boxes are similar to straight tuck boxes, but the top and bottom closure panels fold into the main box from opposite directions.

- Lock bottom boxes are sturdier boxes for holding heavier items. The bottom closure flaps push into each other to form a secure base.

- Crash bottom boxes are also called auto-lock bottom boxes. They have the strongest bottom type for heavy items and feature four tabs that lock into each other for a strong closure.

- One-piece tuck top boxes feature tops that open and close on a fold with tabs that tuck into the main box to form a friction lock.

- Two-piece boxes consist of a separate tray and lid that both have a durable, double-wall structure. The lid fits over the top of the tray, and a box sleeve can be added for an elegant look.

- Holster boxes have an open top. This allows you to display the top part of your product. The bottom can be straight tuck or lock tuck, and the open top can be cut in a custom shape.

- Sleeve packaging is a box sleeve with no ends, designed to slide over another box. These are great for adding more branding or graphics to an existing box.

- Counter display boxes are specifically designed to display products on the shelf. When the top is open, it becomes a raised display panel. When the top is closed, the box can protect products during transit.

- Five-panel hanger boxes are similar to reverse tuck boxes, but they have a hanging panel extending from the back panel. This hanging panel has a hole that allows you to hang the box from hooks for display.

- Boxes with inserts can be any type of box with pieces of paperboard added to secure the product inside. In many cases, these inserts stretch across the box and have holes that contain the product to keep it secure and in place.

- Boxes with custom cutouts are any boxes with pieces of the paperboard cut out to show the product inside. Sometimes these cutouts are covered with clear cellophane windows.

- Boxes with thumb tabs are boxes with added circular cutouts on the main panel of the box. These allow customers to open the box flaps more easily.

What Are Some Applications of Folding Cartons?

Folding cartons are mainly used to market products on store shelves. Retailers often only have a few seconds to attract customer attention, so product packaging should be as eye-catching as possible. Folding cartons are especially useful for storing and displaying food products in bakeries and grocery stores.

Folding cartons can also be sold individually as gift boxes. The limitless selection of designs and configurations gives consumers many options for their particular gifts.

Source Folding Cartons from FOCUSales

Folding cartons are an efficient, economical way not only to protect your products during shipping but also to market your product on store shelves. Folding cartons can be made in a variety of shapes, colors, and sizes, with additional options for customization.

At FOCUSales, we have over 50 years of combined experience as a folding carton manufacturer for a variety of products. We’d love to help you design the right folding cartons for your needs. Contact us today or request a quote to get started.